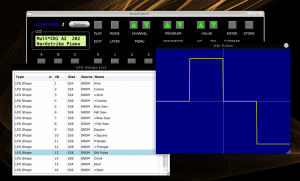

I’ve been intermittently working on my utility program to manage the Kurzweil 1200 Pro synthesizer rack and finally have a bit more to show off. I’ve been struggling to get the basic navigation between menu items working smoothly.

In C++ there is a condition that sometimes occurs when one class is accessing another class, but that other class already uses the first class – it’s known as a circular reference. Unfortunately, I seem to have a lot of this occurring in my program. This is normally a sign of a bad programming architecture and I have been re-factoring as much as I can to separate my presentation and processing logic. I’ve reduced it a lot, and at least the program can function as I intended without too many “forward declarations”. Now that the overall flow is functional, I can start to build out all the extra features. Watch this space!